Description

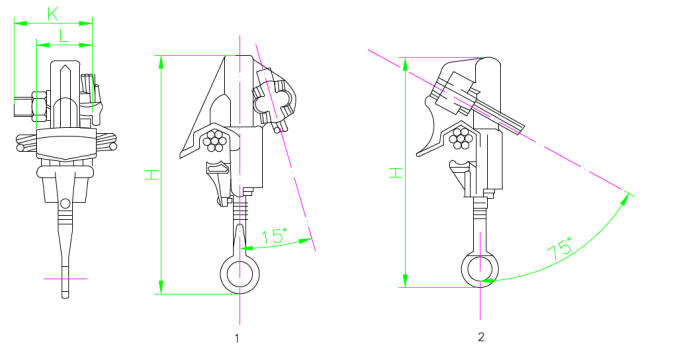

Technical Parameters and Drawings

| Code | Fig No. | L(mm) | H(mm) | K(mm) | EYE BOLT | EYE TAP | MAIN LINE | TAP LINE | MAIN MARK | TAP MARK |

| HESY1520 | 1 | 32 | 130 | 47 | M10X49 | M10X45 | AL 25-70MM2 (3.5-11.35MM) | AL 25-70MM2 (3.5-11.35MM) | 8-2/0 | 8-2/0 |

| HESY1530 | 2 | 47 | 165 | 56 | M12X68 | M10X52 | AL 50-280MM2 (4.11-18.9MM) | AL 50-150MM2 (4.11-13.9MM) | 50-280MM2 | 35-150MM2 |

| Notes:

1. Tolerance: ±5% |

|

| 2. All dimensions are in MM except for marked.

3. Material: aluminum alloy for body, brass or stainless steel eye bolt, and brass tap eye |

|

| 4. Customized sizes are available at request.

|

|

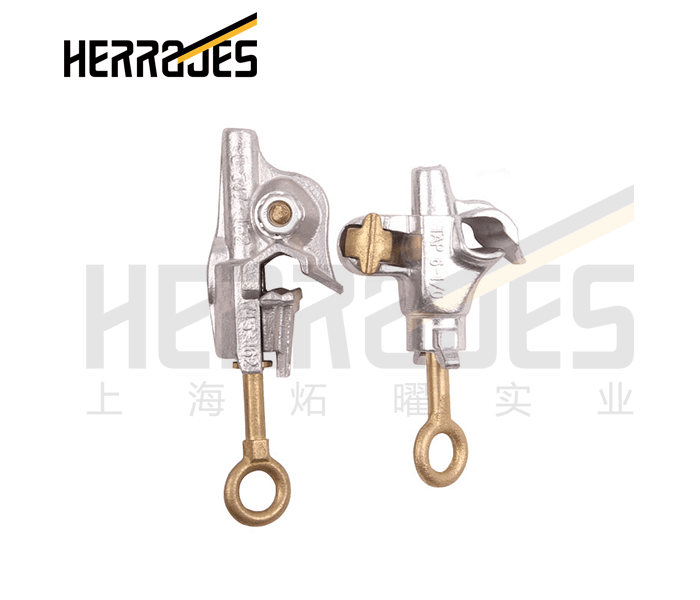

| Product Description:

HESY hot line clamps are designed according to ASTM B686 standard and capable of connect conductors without cutting off the electricity. 3.1.The eye screw threads is attached in a threaded chamber and protected by a corrosion-inhibiting compound effective over a wide temperature range. 3.2.Eye screw threads are isolated from the zone of the arc caused by charging currents. 3.3.The clamp jaws are designed to provide maximum contact with the conductor having current rating of 600 amperes at 75℃. 3.4.The clamp is designed to minimize conductor damage resulting from vibration, and to avoid working of the conductor during tightening. 3.5.Terminal torque and eye screw torque is 300 inch-pounds. 3.6.Both tap connectors and eye screw shall have lock washers fabricated from the materials complying the requirements of ANSlB18.21.1. |

|

| Product Details: | |

| Name: aluminum alloy hot line clamps, conductor clamps | |

| HS code: 7616991090 | |

| Model: HESY | |

| Package: carton packing; palletized; as required | |

| Trademark: HE, as required | |

| Origin: China | |

| Raw material: Aluminum alloy, steel, brass and stainless steel | |

| Finish: Plain | |

| ODM&OEM service: yes | |

| Sample: available, FOC | |

| Payment term: T/T, 30% prepayment and 70% balance against B/L | |

| Certificate: ISO | |

| Delivery time: 20-40 days | |

| MOQ: 500pcs | |

| Export term: FOB; CIF | |

| Production capacity pcs/day: 2000 | |

| Minimum tensile strength lbs.: 7000 | |