What is a ground rod and the applicable standards for ground rods?

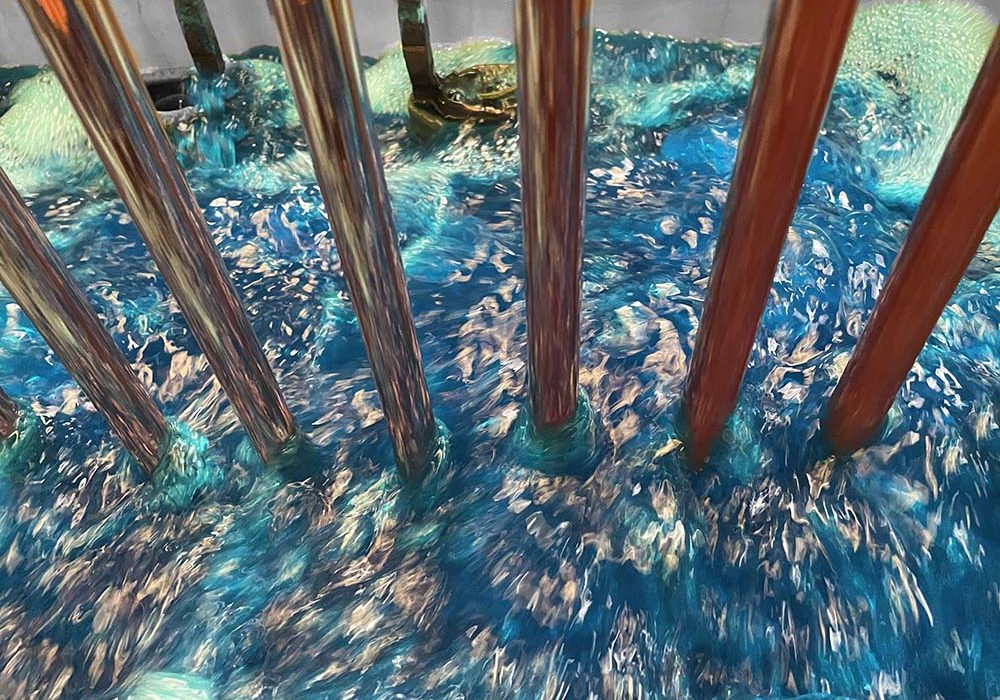

Also known as ground pole, light rod. , the ground rod is designed and produced on the theoretical basis to improve the internal conductivity of the grounding conductor and reduce the external soil conductivity of the grounding conductor.

of. The product has the advantages of simple construction, small footprint, no environmental pollution, long service life and low resistance value.

It is widely used in many fields such as communications, electric power, transportation, finance, petrochemicals, and building systems, such as communication bureaus (stations), mobile base stations, dispatching computer rooms, substations, and highways.

Facilities, computer rooms, intelligent communities and other units and departments that have strict grounding requirements can use this system to form a grounding system with excellent performance. Copper-clad steel materials have good electrical conductivity, high mechanical strength, especially the external copper layer has good corrosion resistance, and has been widely used in grounding devices. America, Britain, Germany, etc.

The state stipulates in relevant standards that both grounding bodies and grounding wires can be made of copper-clad steel composite materials.

Classification:

1. Copper-plated ground rod: The outside of the grounded steel rod is coated with a copper layer with a thickness of more than 0.254mm, which is called copper-plated ground rod, also called copper-clad steel ground rod, etc.

2. Galvanized ground rod: hot-dip galvanizing anti-corrosion treatment on the outside of the steel rod

3. Graphite ground rod: A rod-shaped ground module made of graphite material. This product is still not widely used.

Choose the appropriate grounding rod according to different geological conditions.

Applicated Standard: IEC 62305-3, Protection against lightning – Part 3: Physical damage to structures and life

IEC 62305-3, Protection against lightning – Part 3: Physical damage to structures and life

IEC 62305-4, Protection against lightning – Part 4: Electrical and electronic systems within structures

IEC 62561-1, Lightning protection system components (LPSC) – Part 1: Requirements for connection components

ISO 1460, Metallic coatings – Hot dip galvanized coatings on ferrous materials – Gravimetric determination of the mass per unit area

ISO 1461, Hot dip galvanized coatings on fabricated iron and steel articles – Specifications and test methods

ISO 2178, Non-magnetic coatings on magnetic substrates – Measurement of coating thickness – Magnetic method.

ISO 6892-1:2009, Metallic materials – Tensile testing – Part 1: Method of test at room temperature.

ISO 6957:1988, Copper alloys – Ammonia test for stress corrosion resistance.

ISO 6988:1985, Metallic and other non-organic coatings – Sulfur dioxide test with general condensation of moisture.